ISO 9001:2015 Clause 10

What is the ISO 9001:2015 Clause 10 About?

Clause 10 of the ISO 9001:2015 standard, titled “Improvement,” establishes requirements for continual improvement within a quality management system (QMS). The overall purpose of this clause is to ensure that organizations have processes in place to identify opportunities for improvement, take corrective actions to address nonconformities, and drive ongoing enhancement of their QMS.

Clause 10 underscores the importance of a culture of continual improvement and guides on how organizations can identify opportunities for enhancement. By promoting a systematic approach to analyzing data, implementing corrective actions, and managing change, organizations can foster a culture of innovation, responsiveness, and continuous learning, resulting in sustained business success and customer satisfaction.

The Specific Objectives of Clause 10, Improvement, are as follows:

1. Nonconformity and Corrective Action:

Organizations must establish processes for identifying and addressing non-conformities. This involves determining the root causes of nonconformities, implementing corrective actions to prevent their recurrence, and verifying the effectiveness of those actions. The objective is to address existing issues and prevent similar problems from reoccurring.

Get a Free Quote

2. Continual Improvement:

The clause emphasizes the importance of continually improving the suitability, adequacy, and effectiveness of the QMS. Organizations are required to establish a culture of continual improvement by encouraging employees to contribute ideas, identifying improvement opportunities, and implementing actions to enhance processes, products, and services.

3. Analysis of Data:

Organizations must analyze data collected from monitoring, measurement, and evaluation activities to identify trends, evaluate performance, and identify opportunities for improvement. This data-driven approach helps organizations make informed decisions and prioritize improvement initiatives based on objective information.

4. Management of Change:

The clause requires organizations to establish processes for managing changes that could impact the QMS. This includes assessing the effects of changes, determining the need for adjustments to the QMS, and implementing changes in a planned and controlled manner to maintain the effectiveness of the system.

5. Corrective Action Review:

Organizations must review the effectiveness of corrective actions taken to address nonconformities and identify opportunities for improvement. This involves evaluating the outcomes of corrective actions, monitoring their effectiveness, and identifying any further actions required to achieve desired results.

By addressing the objectives of Clause 10, organizations establish a framework for continual improvement within their QMS. The focus on nonconformity resolution, corrective actions, and ongoing enhancement ensures that organizations are proactive in addressing issues, driving efficiency, and delivering products and services that consistently meet customer requirements.

Complying with Clause 10

Complying with Clause 10, titled “Improvement,” in the ISO 9001 Standard involves establishing processes for continually improving the effectiveness of the quality management system (QMS) and enhancing customer satisfaction. Here are some examples of how an organization can comply with Clause 10:

1. Corrective actions:

Implement a systematic process for addressing nonconformities, including customer complaints, internal nonconformities, and audit findings. Identify the root causes of nonconformities, take corrective actions to eliminate them, and monitor the effectiveness of the actions implemented.

2. Preventive actions:

Implement proactive measures to identify and address potential issues before they occur. Conduct risk assessments, analyze trends and data, and develop preventive action plans to mitigate risks, improve processes, and prevent the occurrence of nonconformities.

3. Continual improvement projects:

Encourage employees to participate in improvement initiatives and projects. Establish a structured approach for identifying improvement opportunities, selecting improvement projects, defining objectives and targets, allocating resources, and tracking progress toward achieving desired outcomes.

4. Management of change:

Establish a process for managing changes within the organization that may impact the QMS. Evaluate the potential consequences of changes, communicate changes to relevant stakeholders, and ensure that appropriate actions are taken to maintain the effectiveness of the QMS during and after the change.

5. Customer feedback and suggestions:

Collect and analyze customer feedback to identify areas for improvement and enhance customer satisfaction. Encourage customers to provide suggestions and recommendations for product or service enhancements, and implement changes based on their input when feasible and beneficial.

6. Analysis of data and metrics:

Regularly analyze data and performance metrics to identify trends, patterns, and opportunities for improvement. This may involve analyzing customer satisfaction data, process performance data, defect rates, on-time delivery metrics, or any other relevant data sources.

7. Employee engagement:

Foster a culture of employee engagement and empowerment in driving improvement initiatives. Encourage employees to provide suggestions for process enhancements, participate in problem-solving activities, and contribute to the identification and implementation of improvement opportunities.

8. Supplier improvement:

Collaborate with suppliers to drive continuous improvement in the supply chain. Share performance data, conduct joint improvement projects, provide feedback on supplier performance, and establish improvement plans to enhance the quality of externally provided products or services.

9. Management review:

Conduct regular management reviews to evaluate the performance of the QMS, identify improvement opportunities, and allocate necessary resources for improvement initiatives. Review quality objectives, audit results, customer feedback, and other relevant information during these sessions.

10. Training and development:

Invest in training and development programs to enhance the skills and knowledge of employees. Provide opportunities for employees to acquire new competencies, learn about emerging best practices, and stay updated on changes in technology or industry standards.

Compliance with Clause 10 ensures that the organization is committed to continually improving its QMS, processes, and overall performance. By implementing corrective and preventive actions, driving improvement projects, managing change effectively, seeking customer feedback, analyzing data, engaging employees, collaborating with suppliers, conducting management reviews, and investing in training and development, organizations can foster a culture of continuous improvement and achieve higher levels of quality and customer satisfaction.

A History of Clause 10 of the ISO 9001 Standard

Clause 10 of the ISO 9001 standard, titled “Improvement,” has evolved throughout the history of the standard. Let’s explore the changes and developments in Clause 10 over the different versions of ISO 9001:

ISO 9001:1987:

The initial version of ISO 9001, published in 1987, did not have a dedicated clause for “Improvement.” The standard primarily focused on quality assurance and control processes, without explicitly addressing the systematic improvement of a quality management system (QMS).

ISO 9001:1994:

In the 1994 revision, ISO 9001 introduced the concept of a “Quality System” in Clause 4. While it addressed some aspects of improvement, there was no dedicated clause specifically addressing this topic.

ISO 9001:2000:

The year 2000 brought significant changes to ISO 9001, including the introduction of the High-Level Structure (HLS) developed by ISO. Clause 8, titled “Measurement, Analysis, and Improvement,” was introduced to address the improvement aspects of the QMS. It included requirements related to the continual improvement of the QMS processes.

ISO 9001:2008:

The 2008 revision retained Clause 8.5, titled “Improvement,” which encompassed requirements related to the continual improvement of the QMS. It emphasized the need for corrective actions and preventive actions to address nonconformities and prevent potential issues.

ISO 9001:2015:

The 2015 revision of ISO 9001 brought significant changes to Clause 10. It was restructured and expanded to provide a more comprehensive approach to improvement within the QMS. The revised clause, titled “Improvement,” includes requirements related to nonconformity and corrective action and the concept of continual improvement.

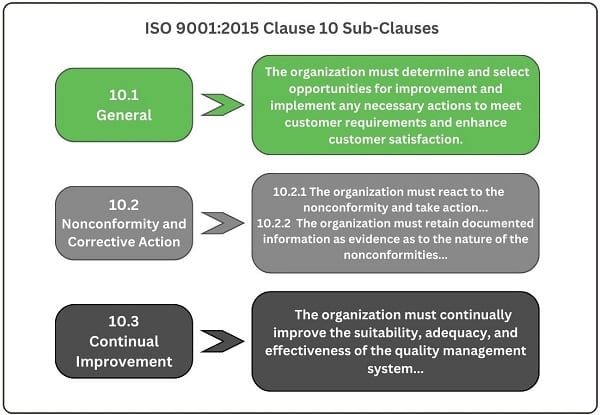

ISO 9001:2015 introduced specific sub-clauses under Clause 10, including:

10.1 General

10.2 Nonconformity and corrective action

10.3 Continual improvement

The current version of ISO 9001, ISO 9001:2015, places significant emphasis on improvement as a fundamental aspect of the QMS. It requires organizations to establish systematic processes for identifying and addressing nonconformities, implementing corrective actions, and driving continual improvement.

By incorporating improvement requirements, ISO 9001:2015 ensures that organizations have mechanisms to address issues, prevent recurrence, and continually enhance their processes, products, and services. It emphasizes the importance of learning from nonconformities, analyzing data, setting improvement objectives, and promoting a culture of continual improvement.

Consulting Support for ISO 9001

Every year, we help hundreds of small businesses achieve ISO 9001 certification. Support for ISO 9001 is available through any of our Consulting Programs

As an American business with a story like yours, we know that time is valuable. Our expert consultants are here to take on the difficult, technical aspects of certification so you can focus on your business. They’ll work with you every step of the way until you’re successfully certified.

Interested? Get a Free Quote.

In many industries, ISO 9001 has become a supply-chain requirement. When landing a big contract, ISO 9001 certification could make all the difference.

About Core Business Solutions

"Core Business Solutions was started by my brother, Mike Dawson, and myself, true entrepreneurs at heart looking for a better way to make a living and help small businesses improve the quality of the products and services they provide.

The bottom line: we are real people that have developed a team to come along side you to help you grow and succeed."

-- Scott Dawson, President

Related Standards

We provide consulting support for various other standards, as well as support for companies seeking multiple certifications through an Integrated Management System.

AS9100

Aerospace Manufacturers

AS9120

Aerospace Distributors

ISO 14001

Environmental Management Systems

ISO 27001

Information Security Management Systems

ISO 20000-1

Service Management Systems

ISO 45001

OH&S Management Systems

ISO 13485

Medical Device Manufacturers

AS9100

AS9120

ISO 14001

ISO

20000-1

ISO 27001

ISO 45001

ISO 13485

Equip Your Business to Meet ISO 9001 With CORE

At Core Business Solutions, we’re here to equip your company for success in meeting ISO 9001 requirements. We’ve helped hundreds of small businesses grow and deliver the best solutions to their clients. We provide ISO training services, consulting help, and compliance software and to help you get certified and stay certified. We focus on optimizing your processes and helping you implement an ISO-compliant QMS. When you partner with us, you’ll get the tools and help you need for success.

For more information on the ISO 9001:2015 standard, please visit our articles page. You can also call our consulting office at 866-354-0300 or contact us online.

Do you want to update your existing ISO 9001 QMS System or refresh it?

We provide consulting services to assist you in your ISO 9001 Quality Management System refresh. We listen, conduct a gap analysis, update your Quality Policy and any necessary documentation or procedures, find areas of waste or improvement, simplify and automate. And we do it fast. Core offers firm, fixed pricing. Download our information sheet today to learn more or call us at 866-354-0300 Extension 2.