ISO 9001:2015 Clause 8.7

What is ISO 9001:2015 Clause 8.7?

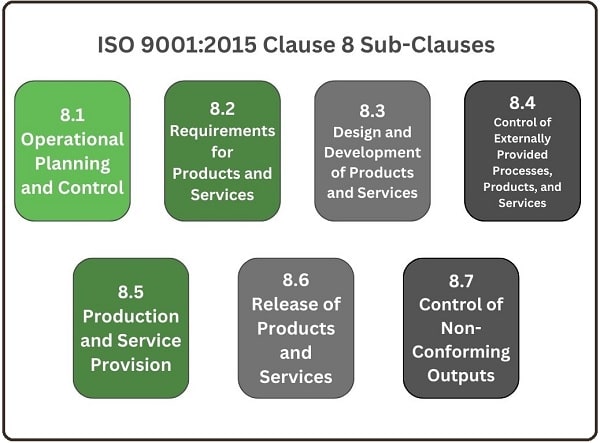

Clause 8.7 of ISO 9001:2015 deals with the control of nonconforming outputs. It outlines the requirements for organizations to address and manage products, services, or processes that do not conform to specified requirements.

Key points outlined in Clause 8.7 include:

Identification:

Establish processes to identify nonconforming outputs. This involves recognizing when a product, service, or process does not meet specified requirements.

Documentation and Evaluation:

Document nonconformities, evaluate their significance, and determine the actions needed to address them. This could involve identifying the root cause of the nonconformity.

Control and Segregation:

Ensure that nonconforming outputs are controlled to prevent unintended use or delivery. This might involve segregation, labeling, or physical isolation of nonconforming items.

Decision Making:

Determine appropriate actions to deal with nonconformities. This could include taking corrective action to eliminate the nonconformity, accepting it under concession, or taking preventive action to avoid its occurrence.

Review and Authorization:

Review and authorize decisions related to the disposition of nonconforming outputs. This might involve involving relevant stakeholders or designated personnel.

Record Keeping:

Maintain records of the nature of the nonconformity, actions taken, and any concessions granted.

Clause 8.7 emphasizes the importance of having processes in place to address nonconformities effectively. It aims to prevent the unintended use or delivery of products, services, or processes that do not meet specified requirements, ensuring that corrective or preventive actions are taken to maintain quality standards.

How do you comply with Clause 8.7?

To comply with Clause 8.7 of ISO 9001:2015, which deals with the control of nonconforming outputs, organizations should follow these steps:

Identification of Nonconformities:

Establish robust processes to identify nonconforming outputs, whether they are products, services, or processes. This involves detecting instances where the output does not meet specified requirements.

Documentation and Evaluation:

Document nonconformities thoroughly, evaluate their significance, and determine appropriate actions to address them. This includes investigating the root cause of the nonconformity.

Control and Segregation:

Implement measures to control nonconforming outputs to prevent their unintended use or delivery. This may involve segregating, labeling, or physically isolating nonconforming items to prevent their use.

Decision Making:

Determine the suitable actions to address nonconformities. This could include initiating corrective actions to eliminate the nonconformity, accepting it under concession, or implementing preventive actions to avoid its recurrence.

Review and Authorization:

Ensure that decisions related to the disposition of nonconforming outputs are reviewed and authorized by relevant stakeholders or designated personnel.

Record Keeping:

Maintain records of nonconformities, actions taken to address them, and any concessions granted. These records serve as evidence of compliance and aid in future assessments and improvements.

By systematically following these steps and implementing effective procedures for identifying, controlling, and addressing nonconforming outputs, organizations can comply with Clause 8.7 of ISO 9001:2015. The aim is to prevent the unintended use or delivery of products, services, or processes that do not meet specified requirements while taking appropriate actions to rectify or manage the non-conformities

What is the History of Clause 8.7?

Clause 8.7 in ISO 9001:2015, concerning the control of nonconforming outputs, evolved alongside the revisions of the ISO 9001 standard:

ISO 9001:1987:

The initial version didn’t have the same structured clauses as later versions. However, the concept of handling nonconformities was present in various sections related to quality control and corrective actions.

ISO 9001:1994:

This version introduced a more systematic approach to quality management systems. Although there wasn’t a specific clause dedicated to controlling nonconforming outputs, the requirements related to corrective actions and quality control addressed the management of nonconformities to a certain extent.

ISO 9001:2000:

The 2000 revision emphasized a process-based approach. While still lacking a standalone clause for controlling nonconformities, the focus on process control and improvement indirectly addressed the need to handle nonconforming outputs.

ISO 9001:2008:

This version continued the emphasis on process management. Although there were no significant changes specifically addressing the control of nonconformities, the principles of quality management highlighted the importance of managing deviations from requirements.

ISO 9001:2015:

The current version introduced Clause 8.7, explicitly focusing on the control of nonconforming outputs. This clause emphasizes the need to identify, document, evaluate, control, and take appropriate actions regarding nonconformities to prevent their unintended use or delivery.

Over time, the ISO 9001 standard evolved to place more explicit emphasis on the control and management of nonconforming outputs, culminating in the inclusion of Clause 8.7 in the 2015 version. This clause provides a structured approach for organizations to address nonconformities effectively within their quality management systems.

Helpful Resources: ISO Audits – ISO 9001 and Supplier Management

In this podcast episode, host Xavier Francis interviews Kaitlin Wierzbach, consultant at Core Business Solutions, about ISO 9001 supplier management. They discuss the significance of supplier management for businesses and highlight the key elements of an effective system. Kaitlin emphasizes the importance of identifying, qualifying, and evaluating suppliers to ensure consistent delivery of quality products and services. Listen Now

Consulting Support for ISO 9001

Every year, we help hundreds of small businesses achieve ISO 9001 certification. Support for ISO 9001 is available through any of our Consulting Programs As an American business with a story like yours, we know that time is valuable. Our expert consultants are here to take on the difficult, technical aspects of certification so you can focus on your business. They’ll work with you every step of the way until you’re successfully certified. Interested? Get a Free Quote.

In many industries, ISO 9001 has become a supply-chain requirement. When landing a big contract, ISO 9001 certification could make all the difference.

About Core Business Solutions, Inc.

— Scott Dawson, President

Related Standards

We provide consulting support for various other standards, as well as support for companies seeking multiple certifications through an Integrated Management System.

AS9100

Aerospace Manufacturers

AS9120

Aerospace Distributors

ISO 14001

Environmental Management Systems

ISO 27001

Information Security Management Systems

ISO 20000-1

Service Management Systems

ISO 45001

OH&S Management Systems

ISO 13485

Medical Device Manufacturers

AS9100

AS9120

ISO 14001

ISO

20000-1

ISO 27001

ISO 45001

ISO 13485

Equip Your Business to Meet ISO 9001 With CORE

At Core Business Solutions, we’re here to equip your company for success in meeting ISO 9001 requirements. We’ve helped hundreds of small businesses grow and deliver the best solutions to their clients. We provide ISO training services, consulting help, and compliance software and to help you get certified and stay certified. We focus on optimizing your processes and helping you implement an ISO-compliant QMS. When you partner with us, you’ll get the tools and help you need for success. For more information on the ISO 9001:2015 standard, please visit our articles page. You can also call our consulting office at 866-354-0300 or contact us online.

Do you want to update your existing ISO 9001 QMS System or refresh it?

We provide consulting services to assist you in your ISO 9001 Quality Management System refresh. We listen, conduct a gap analysis, update your Quality Policy and any necessary documentation or procedures, find areas of waste or improvement, simplify and automate. And we do it fast. Core offers firm, fixed pricing. Download our information sheet today to learn more or call us at 866-354-0300 Extension 2.